I am getting tired of sitting in front of the computer almost daily working on track planning. I feel the need to get something moving down in the basement. I have decided to start construction of a test module to get my feet wet, based on an idea I picked up from Chris Ellis on his Adena Railroad blog.

I have a pair of 18" x 80" hollow core doors (actual measurements are 17.75" x 79") that I have had laying around for a few years that I was at some point going to use to start making a shelf layout with at my old house but never really got around to doing. They came in a bi-fold door pack that was under $50 for the two doors. The beauty of hollow core doors is that they are lightweight yet strong and they are highly resistant to warping or sagging.

The module is going to be a fully operational diorama-style mini layout wired for DCC. Right now I am going to build it on a tabletop but at some point I will most likely end up mounting it on the wall using shelf brackets or possibly making a folding leg type of benchwork for it.

I thought about mounting polystyrene foam on the entire module top but decided against it. I will just use the foam as needed if I decide to create some terrain features. Right now the idea is to make this a flat urban type area with little to no terrain features. So, I decided that I would try mounting 3/8" drywall on top of the door and then covering that with a 1/8" thick sheet of cork which I already have a few rolls of. I have seen some other modelers on the web that are using a plywood/drywall/cork (or other soft material) sandwich instead of polystyrene and have been curious to see how it works. Same thing here except instead of a plywood base I am using a hollow core door. I can use more of the cork sheeting layered as roadbed under any track that is to have a thicker ballast bed than flat yard & industrial track.

I used standard drywall screws to attach the drywall sheets to the top of the door. The hollow core door has a rigid wood frame around the edges so the screws were driven through the drywall and into the frame of the door. I used a surform around the edges of the drywall to smooth it before attaching the cork. The cork sheet was glued down with yellow glue spread out thin with a 9" drywall knife. I am not too concerned about the edges of the cork and drywall being perfect because to finish the module off I will attach a masonite fascia all the way around.

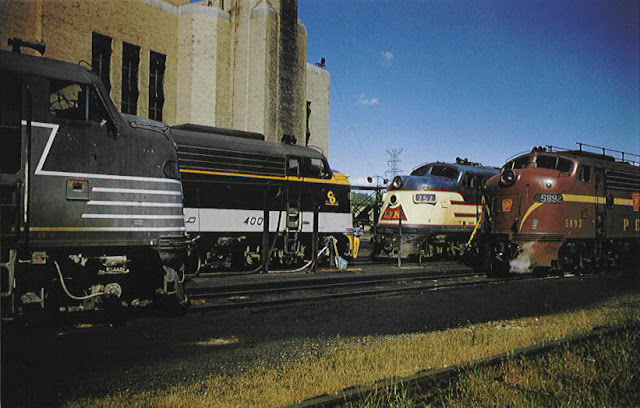

I have several ideas I want to try with this module. One of the things I want to test is how 85' passenger cars behave in crossovers. The plan on my larger layout is to use higher numbered turnouts on mainlines, not only because they look more prototypical but also for their performance with the longer passenger cars. For this first test, I have some Central Valley #9 turnouts that I will be using. While I don't consider Central Valley turnouts to be truely handlaid track, they will give me an opportunity to try my hand at making turnouts almost from scratch. I also have some #7 turnouts, also by Central Valley, and a couple bags of Central Valley tie strips, both mainline and branchline tie spacing, for the rest of the track. Mainline track will be code 83 and everything else will be code 70.

I like the appearance of the CVT turnouts and ties. They have good tieplate detail and the turnout kits are self-gauging. Each turnout kit comes with a set of cast metal points and a set of styrene superdetailing parts, including a target style switchstand. The best part about them is they are quite inexpensive compared to commercial turnouts.

A simple track plan is all that is necessary and is really all that will fit. In the next part, I will start mocking up the plan to see how it looks.

I have a pair of 18" x 80" hollow core doors (actual measurements are 17.75" x 79") that I have had laying around for a few years that I was at some point going to use to start making a shelf layout with at my old house but never really got around to doing. They came in a bi-fold door pack that was under $50 for the two doors. The beauty of hollow core doors is that they are lightweight yet strong and they are highly resistant to warping or sagging.

The module is going to be a fully operational diorama-style mini layout wired for DCC. Right now I am going to build it on a tabletop but at some point I will most likely end up mounting it on the wall using shelf brackets or possibly making a folding leg type of benchwork for it.

I thought about mounting polystyrene foam on the entire module top but decided against it. I will just use the foam as needed if I decide to create some terrain features. Right now the idea is to make this a flat urban type area with little to no terrain features. So, I decided that I would try mounting 3/8" drywall on top of the door and then covering that with a 1/8" thick sheet of cork which I already have a few rolls of. I have seen some other modelers on the web that are using a plywood/drywall/cork (or other soft material) sandwich instead of polystyrene and have been curious to see how it works. Same thing here except instead of a plywood base I am using a hollow core door. I can use more of the cork sheeting layered as roadbed under any track that is to have a thicker ballast bed than flat yard & industrial track.

I used standard drywall screws to attach the drywall sheets to the top of the door. The hollow core door has a rigid wood frame around the edges so the screws were driven through the drywall and into the frame of the door. I used a surform around the edges of the drywall to smooth it before attaching the cork. The cork sheet was glued down with yellow glue spread out thin with a 9" drywall knife. I am not too concerned about the edges of the cork and drywall being perfect because to finish the module off I will attach a masonite fascia all the way around.

I have several ideas I want to try with this module. One of the things I want to test is how 85' passenger cars behave in crossovers. The plan on my larger layout is to use higher numbered turnouts on mainlines, not only because they look more prototypical but also for their performance with the longer passenger cars. For this first test, I have some Central Valley #9 turnouts that I will be using. While I don't consider Central Valley turnouts to be truely handlaid track, they will give me an opportunity to try my hand at making turnouts almost from scratch. I also have some #7 turnouts, also by Central Valley, and a couple bags of Central Valley tie strips, both mainline and branchline tie spacing, for the rest of the track. Mainline track will be code 83 and everything else will be code 70.

I like the appearance of the CVT turnouts and ties. They have good tieplate detail and the turnout kits are self-gauging. Each turnout kit comes with a set of cast metal points and a set of styrene superdetailing parts, including a target style switchstand. The best part about them is they are quite inexpensive compared to commercial turnouts.

|

| Note the tieplate detail |

|

| Superdetailing and parts kit included with each CV turnout. |

|

| Another view of the tieplate detail. |

|

| What you get in each CV turnout kit. |

A simple track plan is all that is necessary and is really all that will fit. In the next part, I will start mocking up the plan to see how it looks.